What Is Crepe Fabric? Properties, How It’s Made & Where It Comes From

Crepe fabric is one of the most loved textiles in modern fashion....

The demand for scuba fabric is rising as apparel brands seek textiles that combine structure, stretch, and sleek finishes. In 2024, the U.S. textile market reached an estimated USD 188.3 billion, and it is projected to grow to about USD 277.4 billion by 2033 at a CAGR of 4.1 %. Meanwhile, the global textile market is anticipated to nearly double, rising from ~USD 1,976.8 billion in 2024 to over USD 4,016.5 billion by 2034, with a compound annual growth rate (CAGR) of ~7.35%.

Within this rapidly evolving landscape, technical and fashion-forward fabrics are gaining increasing prominence. Scuba fabric, with its blend of durability and aesthetic appeal, stands out as an emerging favorite for brands that want bold silhouettes without sacrificing comfort.

In this article, we’ll explain exactly what scuba fabric is, examine its properties and applications, compare it to neoprene, and explore why it’s trending in modern apparel, especially for U.S.-based designers, private label brands, and performance wear startups, while also showing how Seam Apparel can help brands source and manufacture scuba-based garments.

Scuba fabric is a double-knit material made by blending polyester and spandex. It is often mistaken for neoprene, but the two are quite different. Unlike neoprene, which is a thick foam used in wetsuits, scuba fabric is lightweight, smooth, and designed for fashion and performance apparel.

Because of these qualities, scuba fabric has gained popularity in the US fashion industry, especially among private label brands, activewear companies, and modern designers.

The fabric is known for its:

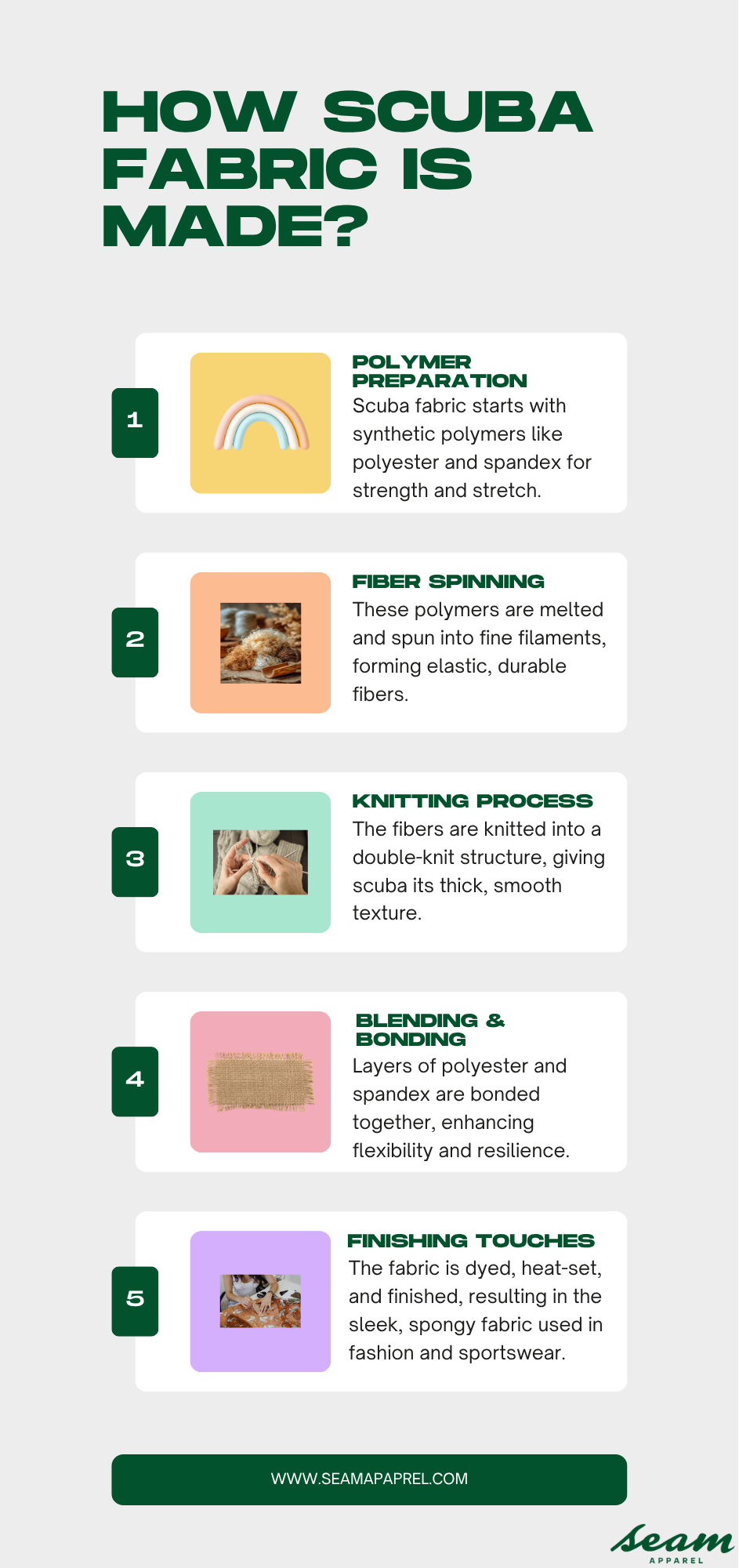

Scuba fabric is crafted from synthetic fibbers, most commonly polyester blended with a small percentage of spandex. This combination gives the fabric its unique balance of structure and stretch, making it both durable and comfortable.

The foundation of scuba fabric lies in its double-knit method, produced on circular knitting machines. Unlike single-knit fabrics, this technique creates two layers of interlocked yarns, resulting in a thicker, denser structure with a smooth surface. This construction is what gives scuba its firm body and wrinkle resistance, making it stand out among performance and fashion textiles.

A small percentage of spandex is integrated into the polyester base to provide 4-way stretch. This ensures that garments made from scuba fabric move comfortably with the body while maintaining their shape. The spandex also enhances recovery, preventing sagging after repeated wear.

Once knitted, the fabric undergoes dyeing and chemical finishing. This stage adds vibrant color options, improves durability, and gives the fabric its sleek, polished appearance. Some treatments may also enhance stain resistance or improve the fabric’s smooth hand feel, depending on end-use requirements.

Together, these steps result in a textile that is uniform, strong, and versatile qualities that make scuba fabric suitable for athleisure, structured fashion garments, and performance wear. Its precise construction also allows designers to create bold silhouettes without sacrificing comfort.

Also check: Pima Cotton Fabric: What It Is, How It’s Made & Why Premium Brands Love It

Scuba fabric combines style and function, making it a go-to choice for many apparel categories.

Key properties include:

These features allow scuba fabric to support sharp silhouettes, body-hugging designs, and performance-based clothing.

Also check: Learn in detail about fabrics: Polyester and cotton blend

Scuba fabric comes in several variations, each offering unique textures and applications:

To preserve its structure and sleek appearance, scuba fabric requires careful handling:

Providing clear care labels is essential for brands to ensure customer satisfaction and extended fabric life.

Also check: Eco-Friendly Materials for Clothing: A Sustainable Fashion Guide

This adaptability has made scuba fabric a favorite among US athleisure brands and fashion startups. Because of its versatility, scuba fabric is used in both fashion-forward and functional garments.

Although they look similar, scuba fabric and neoprene serve quite different purposes.

| Feature | Scuba Fabric | Neoprene |

|---|---|---|

| Structure | Lightweight double knit | Heavier with foam core |

| Stretch | Excellent (thanks to spandex) | Minimal |

| Breathability | Moderate | Low |

| Water Resistance | Not waterproof | Water-resistant |

| Fashion Use | High (jackets, dresses, activewear) | Limited (mostly wetsuits) |

In short, scuba is for fashion and performance apparel, while neoprene is designed for functional water resistance.

For US-based brands aiming to balance performance and responsibility, sourcing recycled scuba is becoming an attractive option. Like most synthetic fabrics, scuba fabric is not inherently eco-friendly. It is primarily made from polyester, which is not biodegradable.

However, there are some sustainability considerations:

At Seam Apparel, as a private label manufacturer, scuba fabric is one of the materials offered for structured fashion and performance-driven designs.

This makes scuba fabric an excellent choice for brands looking to combine style and performance in their apparel lines.

Scuba fabric is more than just a trend; it’s a modern textile solution for designers and brands who want bold, structured, and functional clothing. With its sleek finish, shape retention, and versatile applications, it bridges the gap between high fashion and activewear.

For US-based brands and startups exploring scuba fabric manufacturing, Seam Apparel provides expertise in sourcing, design support, and flexible production. Whether you’re creating fashion-forward dresses or technical active wear, scuba fabric offers the durability and style needed to stand out.

Looking to explore scuba fabric for your brand? Contact Seam Apparel for fabric consultation, prototyping, or sampling.