Our Process

At Seam Apparel, we follow a clear, reliable, and transparent apparel manufacturing process. Every step is designed to turn your idea into a finished garment that is ready for the market.

We work closely with startups, private labels, designers, and established brands that need a dependable manufacturing partner.

Our clothing manufacturing process is simple to understand and easy to follow. From the first discussion to final delivery, we focus on quality, accuracy, and clear communication. You always know what is happening at every stage.

This page explains how clothes are made at Seam Apparel. It shows how we manage the full fashion production process, from concept to bulk production. Our goal is to help you feel confident, informed, and supported throughout your journey.

Production Transparency & Clear Communication

Clear communication is a core part of our apparel manufacturing process. We understand that delays and confusion can impact launches and sales. That is why we keep our clients informed at every stage of production.

From sampling updates to production milestones, our team provides regular progress reports. Any questions about materials, timelines, or adjustments are addressed quickly and clearly. This transparency allows you to make informed decisions without stress.

Our structured workflow ensures smooth coordination between design, sampling, garment production, and quality control. You are never left guessing about the status of your order. This level of openness is especially valuable for startups and private label brands managing production for the first time.

By combining technical expertise with clear communication, we help brands move through the clothing manufacturing process with confidence and control.

Step 1 :

Concept & Design Consultation

Every successful garment starts with a clear idea.

Our process begins with detailed apparel design development.

You can come to us with a sketch, reference images, mood boards, or an existing tech pack. If your idea is still rough, our team helps shape it into a production-ready concept.

During this stage, we focus on:

- Understanding your brand identity

- Defining your target customer

- Discussing fit, style, and garment purpose

- Planning timelines and development steps

We also support product development services, including tech pack guidance, measurement charts, and construction suggestions. Our experience helps you avoid costly mistakes before sampling begins.

This step sets the foundation for the entire apparel manufacturing process. A strong start leads to smoother production later.

Step 2 :

Fabric Sourcing & Material Selection

Fabric plays a major role in garment quality and performance.

Seam Apparel offers complete fabric sourcing services for a wide range of apparel categories.

We help you choose the right fabric based on your design, budget, and end use. Our sourcing team collaborates with trusted suppliers to ensure consistency and quality.

We source materials such as:

- Cotton and organic cotton

- Denim and twill

- Polyester and recycled polyester

- Jersey, rib, and interlock knits

- Fleece and performance blends

For brands focused on responsibility, we also offer sustainable fabric sourcing options. These include recycled fibers and eco-conscious materials where available.

Our team explains fabric weight, stretching, durability, shrinkage, and care requirements. This helps you make informed decisions during the fabric selection stage of the fashion production process.

Step 3 :

Pattern Making & Sample Development

Once fabrics are confirmed, we move into pattern making and sampling.

This stage turns your design into a wearable garment.

Our technical team creates accurate patterns based on your measurements and fit requirements. Patterns are digitized to ensure consistency across sizes and future production runs.

The apparel sampling process includes:

- First prototype development

- Fit testing and evaluation

- Design adjustments and revisions

- Final sample approval

Through careful prototype development, we refine construction, proportions, and finishing. You review the sample and provide feedback before moving forward.

Sampling ensures your garment fits well, looks right, and performs as expected. It is a critical step in the clothing manufacturing process and helps reduce production risks.

Step 4 :

Cut & Sew Manufacturing

After sample approval, bulk production begins.

This is where Seam Apparel’s garment production expertise comes into play.

Our cut & sew manufacturing process is managed by skilled production teams who follow approved patterns and specifications. Precision and consistency are maintained at every stage.

Production includes:

- Fabric inspection and cutting

- Stitching and assembly

- Seam reinforcement and finishing

- In-line quality checks

We oversee a wide range of apparel categories, from casual wear to performance garments. Our production workflow is designed to support both small launches and growing collections.

Throughout this stage, we maintain strict control over sizing, stitching quality, and overall construction. This ensures every piece matches the approved sample.

Step 5:

Quality Control & Final Inspection

Quality is never an afterthought at Seam Apparel.

Our process includes multiple checkpoints for garment inspection and quality assurance in apparel manufacturing.

Every order goes through structured quality checking before packaging.

Our inspection standards focus on:

- Stitching strength and accuracy

- Measurement and size consistency

- Fabric defects and color matching

- Label placement and finishing quality

This level of apparel quality control ensures that your garments meet market expectations and brand standards. Only approved pieces move forward to packaging and delivery.

Reliable quality assurance builds trust with your customers and protects your brand reputation.

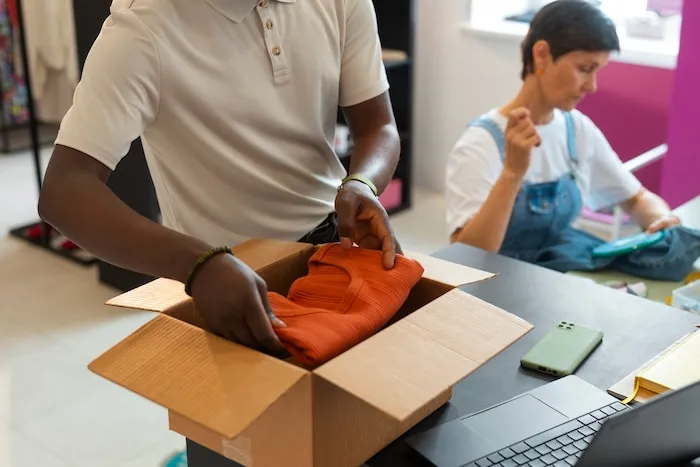

Step 6:

Private Labelling, Packaging & Delivery

Once garments pass final inspection, we prepare them for shipment.

Seam Apparel offers full private-label support and packaging solutions.

This stage includes:

- Custom woven or printed labels

- Hangtags and size tags

- Branded or neutral packaging

- Eco-friendly packaging options

We coordinate packing according to your requirements, whether for retail, wholesale, or direct-to-consumer distribution.

Our logistics team manages shipping coordination to ensure timely delivery. Clear communication keeps you informed until your order reaches its destination.

This final step completes the apparel manufacturing process with care and accuracy.

What sets us apart:

- Over 10 years of apparel industry experience

- In-house design, pattern making, and sampling

- Transparent communication at every stage

- Flexible MOQs to support growth at every level

- Reliable timelines and consistent quality

We understand the challenges of building and scaling a clothing brand. Our process is designed to reduce complexity and give you confidence from start to finish.

Whether you are launching your first collection or expanding an existing line, we adapt our clothing manufacturing process to meet your needs.

We focus on building trust through honesty, craftsmanship, and long-term support. When brands work with Seam Apparel, they gain a manufacturing partner that is committed to their success.

Let’s Build Your Next Collection Together

Your apparel idea deserves a manufacturing partner you can trust. Seam Apparel is ready to support your brand with a clear process, skilled production, and dependable results.If you are looking for a partner who understands the full fashion production process and delivers quality at every step, we are here to help.

Contact Seam Apparel today to discuss your project, request a quote, or start your next collection with confidence.

Your apparel journey begins here