What Is Denim Fabric? Properties, How It’s Made & Where It’s Used

Denim fabric is one of the most recognized textiles in the global...

Polytetrafluoroethylene fabric, commonly known as PTFE fabric, is one of the most advanced materials used in today’s technical apparel market. If you’ve ever wondered what PTFE fabric is? Or how polytetrafluoroethylene fabric in textiles functions, it’s a next-generation performance material designed for durability, chemical resistance, heat protection, and long-term reliability.

The global PTFE fabric market was estimated at around USD 853.6 million in 2024 and is projected to grow to approximately USD 1.5 billion by 2034. Originally developed from Teflon®, PTFE has become a staple for high‑performance textiles in workwear, outdoor clothing, sportswear, and protective uniforms.

SEAM Apparel, our team has expertise in sourcing and working with advanced fabrics like PTFE, helping brands, startups, and designers integrate these technical materials into custom clothing lines. If you’re developing waterproof outerwear or heat-resistant uniforms, PTFE fabric opens doors to innovation and performance.

PTFE fabric is a synthetic fluoropolymer textile made from the polymerization of tetrafluoroethylene monomers. It’s a high-performance material known for its durability, chemical resistance, and non-stick properties. While it’s commonly associated with Teflon®, PTFE in fabric form often appears as a membrane or coated textile, providing waterproofing and protective qualities for apparel.

This fabric is widely used in technical and industrial applications because it combines flexibility with resilience. PTFE-coated fabric can be layered over base textiles like polyester, fiberglass, or nylon to create garments that withstand harsh environments without compromising comfort. Its lightweight yet strong structure makes it ideal for high-performance sportswear, outdoor jackets, industrial uniforms, and protective workwear.

SEAM Apparel, as a private label manufacturer, works closely with material suppliers to incorporate PTFE and other advanced fabrics into custom clothing production, ensuring that every piece meets the rigorous demands of modern apparel brands.

PTFE fabric is a synthetic fluoropolymer textile produced through the polymerization of tetrafluoroethylene monomers.

The result is a high-performance fabric known for:

In textiles, PTFE commonly appears in two main forms:

Because of its strength, lightweight structure, and resistance to extreme conditions, PTFE fabric is widely used in:

PTFE fabric properties make it a standout choice for technical and performance wear.

Here’s a detailed look at what makes this material so valuable:

| Property | Description |

|---|---|

| Water & Stain Resistance | Naturally hydrophobic material that repels water, moisture, and dirt effectively. |

| Heat Resistance | Withstands temperatures up to ~260°C, ideal for high-heat and industrial environments. |

| Chemical Resistance | Highly resistant to acids, alkalis, and most solvents, ensuring long-term fabric protection. |

| Durability | Exceptional tensile strength and wear resistance, suitable for long-lasting performance. |

| Non-Stick Surface | Low-friction, smooth texture prevents adhesion, buildup, and contamination. |

| Breathability (Membrane Use) | As a membrane, it allows airflow while blocking water—perfect for outdoor and technical apparel. |

These properties make PTFE fabric versatile across multiple industries. For apparel designers, it ensures clothing that performs under extreme conditions. For industrial applications, it provides reliable protection against heat, chemicals, and wear. SEAM Apparel leverages these properties to deliver functional, high-quality custom apparel to brands across the USA.

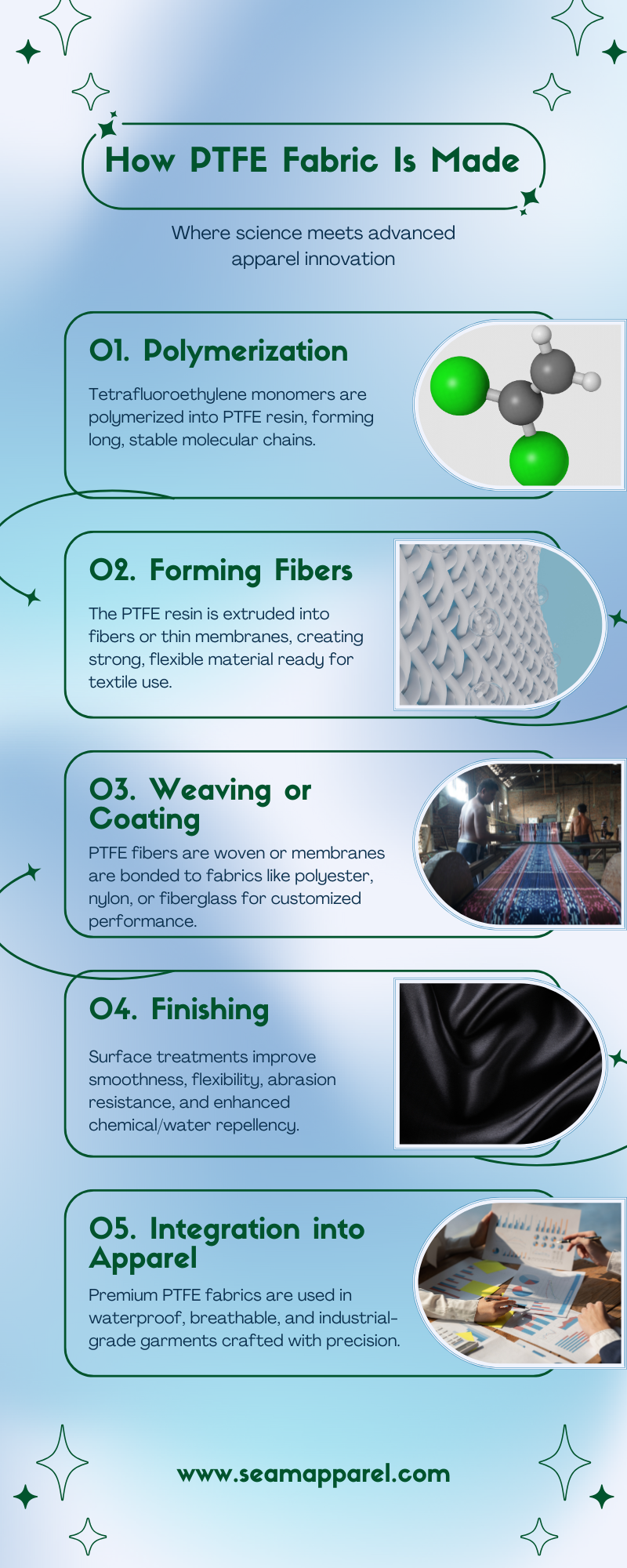

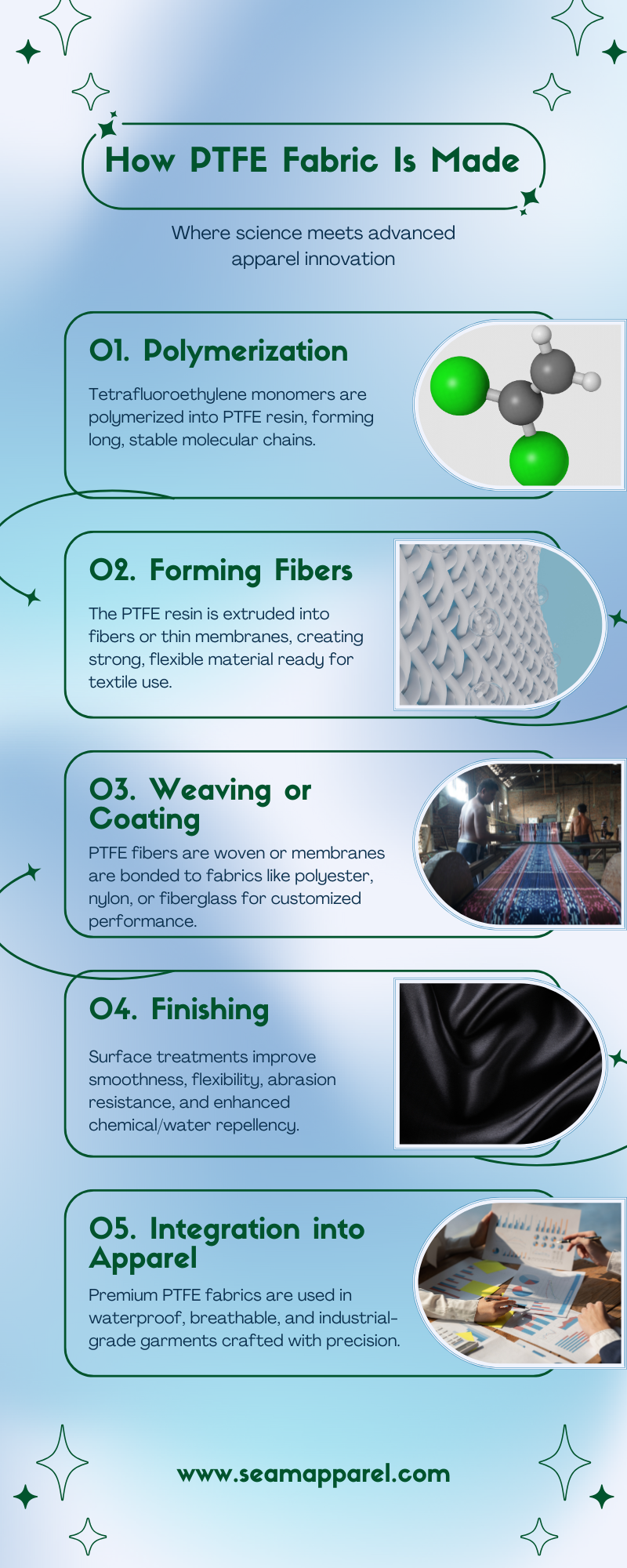

Understanding how PTFE fabric is made provides insight into why it performs so well in both apparel and industrial applications. The manufacturing process involves several precise steps that transform raw chemicals into high-performance textiles.

At SEAM Apparel, we carefully select and partner with trusted suppliers to source premium PTFE fabrics. This collaboration allows us to integrate these advanced materials seamlessly into custom garments.

Learn more about Milk Fabric in our blog.

PTFE fabric’s exceptional combination of durability, chemical resistance, and heat tolerance makes it suitable for a wide range of applications, from technical apparel to demanding industrial environments. Its adaptability ensures that designers, manufacturers, and sourcing professionals can rely on it for both functional and high-performance needs.

PTFE fabric is a go-to material for waterproof jackets, parkas, shell layers, and raincoats designed for hiking, camping, and extreme weather conditions. Its water and stain resistance, combined with breathability, make it ideal for outdoor enthusiasts who need protection without sacrificing comfort.

Protective clothing for chemical handling, laboratories, and heat-intensive workplaces benefits from PTFE’s chemical inertness and heat resistance. These uniforms reduce the risk of accidents, maintain durability in harsh conditions, and provide reliable long-term protection for employees.

Athletes require fabrics that balance performance and comfort. PTFE-coated fabrics or membranes offer waterproof yet breathable solutions for sportswear, keeping users dry without restricting movement. This makes it perfect for running jackets, cycling gear, and performance outerwear.

For specialized occupational environments like cleanrooms, manufacturing facilities, and research labs, PTFE fabric provides contamination control and chemical resistance. Its smooth, non-stick surface prevents particles from adhering, maintaining hygiene and safety standards while offering comfort during long shifts.

PTFE-coated conveyor belts are widely used in food processing, packaging, and chemical industries. The smooth, low-friction surface ensures durability, reduces product contamination, and resists wear from constant operation.

PTFE membranes in expansion joints provide both flexibility and chemical resistance. They help accommodate structural movement in industrial installations while maintaining a reliable barrier against liquids and gases.

PTFE fabrics serve as filtration layers in air and liquid filtration systems. Their chemical and heat resistance make them suitable for industrial processes, laboratories, and HVAC systems that require high-performance filtering without degradation.

PTFE’s non-reactive and heat-resistant properties make it ideal for gaskets, seals, and insulation layers in machinery, piping, and electrical equipment. This ensures long-lasting performance even under extreme temperatures or corrosive conditions.

By bridging apparel and industrial applications, PTFE fabric proves its versatility. SEAM Apparel leverages this adaptability to develop custom solutions tailored to both fashion brands and technical industries. From performance outerwear to protective workwear and industrial materials, we ensure that each PTFE-based product meets rigorous functional requirements while maintaining quality and comfort for end users.

| Advantages | Limitations |

|---|---|

| Highly waterproof and extremely durable | Higher cost compared to standard fabrics |

| Chemically inert and resistant to corrosion | Difficult to dye or print effectively |

| Heat-resistant up to ~260°C, ideal for extreme environments | Requires specialized machinery during production |

| Excellent non-stick and low-friction surface performance | Not biodegradable, and recycling options are still limited |

| Long service life with consistent performance reliability | Limited color range available |

Despite limitations, PTFE fabric remains a leading choice for protective and technical wear.

PTFE fabric is not just a high-performance textile today; it’s evolving rapidly to meet new demands in both apparel and industrial applications. Manufacturers and brands are exploring innovative ways to enhance their functionality, sustainability, and design versatility.

Researchers and textile engineers are developing PTFE laminates combined with other technical fabrics like nylon, polyester, or Kevlar. These hybrid materials improve abrasion resistance, stretchability, and breathability while maintaining PTFE’s signature water, chemical, and heat resistance. Such innovations are especially valuable in performance outerwear, extreme sports gear, and specialized industrial uniforms.

While traditional PTFE fabric is not biodegradable, manufacturers are experimenting with recyclable PTFE membranes and coatings to reduce environmental impact. Some approaches involve recovering PTFE from industrial scrap or developing blended membranes that retai