What is Neoprene fabric? What it is, how it’s made, and where it’s used

Neoprene is a new type of performance fabric that is noted for...

Velvet is one of the most recognizable luxury textiles in the fashion and upholstery industries. Known for its soft surface, rich color, and smooth sheen, velvet has been used for centuries in premium garments and decorative interiors. While it was once made only from silk and available only to royalty, modern fiber innovations have made velvet fabric accessible to a wide range of designers, brands, and manufacturers across the USA.

Today, velvet fabric comes in cotton, silk, polyester, rayon, and blended variations, giving apparel designers greater flexibility in performance, drape, durability, and price. Many brands work with manufacturing partners experienced in specialty fabrics. SEAM Apparel often supports designers who want to introduce velvet-based styles into their collections.

This guide explains what velvet fabric is, how it is produced, its characteristics, the many types of fabric, and how designers can select the right option for their product line.

Velvet fabric is a woven material created with a dense upright pile, which forms its plush, soft texture. The pile is made from additional yarn that stands vertically from the base fabric. This gives velvet its depth, sheen, and smooth, touchable surface.

Traditionally, velvet was made from pure silk.

Modern velvet material uses:

Velvet belongs to the broader category of pile fabric, which also includes velour and velveteen. The unique construction allows velvet to display rich color saturation and a distinct reflective surface.

| Feature | Description |

|---|---|

| Type | Woven pile fabric |

| Textures | Smooth, luxurious, dense |

| Common Fibers | Silk, cotton, rayon, polyester, and blended fibers |

| Key Traits | High sheen, rich color depth, exceptionally soft feel |

The history of velvet stretches back to the Middle East around the 14th century. Early velvet was woven from fine silk and used as a symbol of wealth and social status. As trade expanded, the fabric reached Europe, where aristocracy and royal families adopted it.

Because silk velvet required advanced weaving techniques and skilled artisans, it remained expensive for centuries. With the Industrial Revolution, manufacturers introduced cotton-based velvet and synthetic velvet, making production faster, more affordable, and more accessible to global markets, including the USA.

Today, velvet is widely used in both luxury and everyday products, from evening gowns to furniture upholstery.

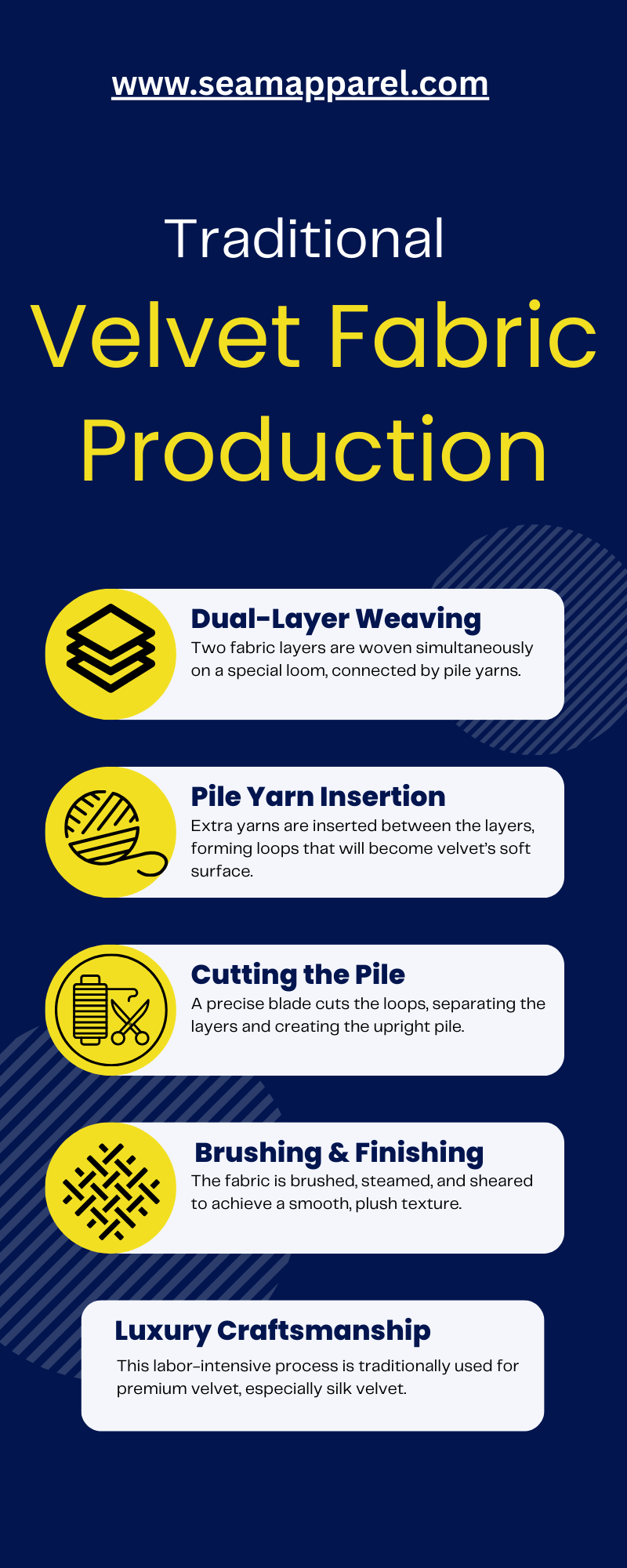

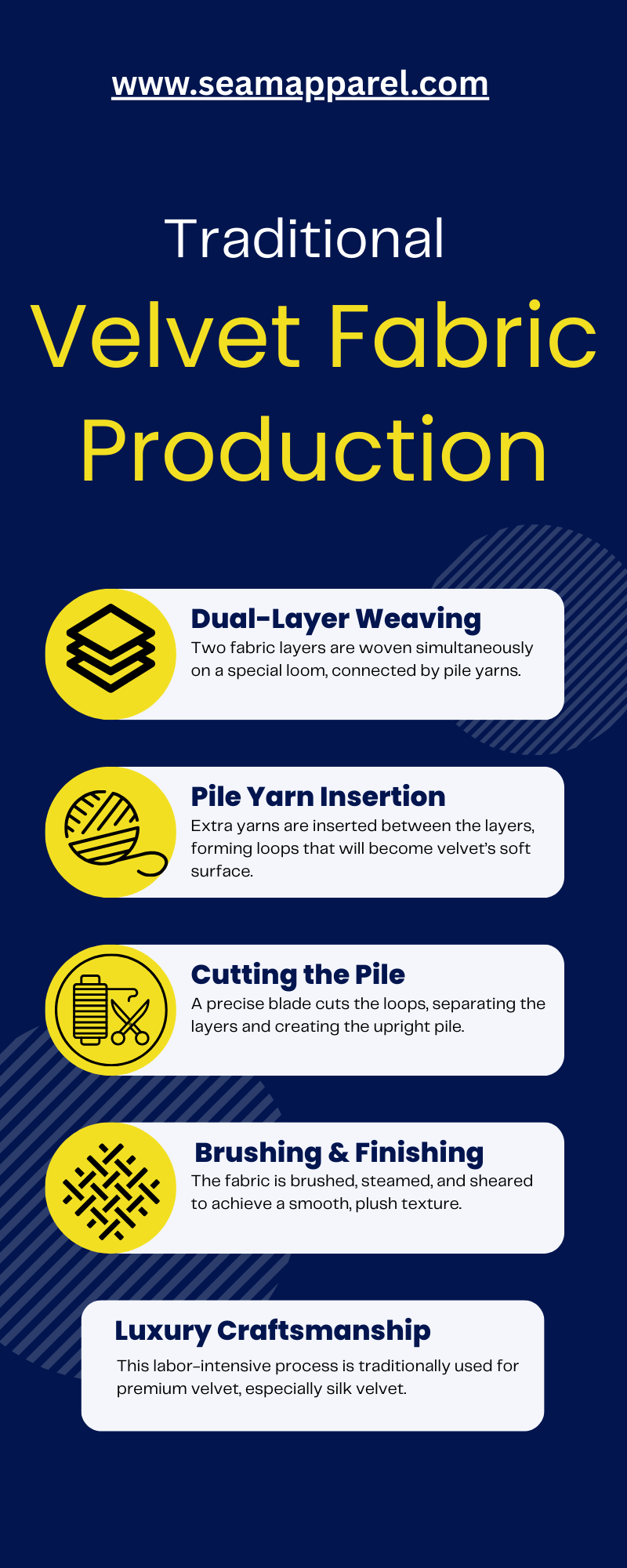

Understanding how velvet is made helps designers appreciate its texture, price, and performance. Velvet’s construction involves a unique weaving technique that forms the characteristic pile.

Two layers of fabric are woven at the same time on a specialized loom. Pile yarns connect the layers.

Extra yarns are inserted between the layers to create loops.

A blade slices these loops, separating the two layers and releasing the upright pile.

The surface is brushed, steamed, and sheared to achieve a uniform, plush finish.

This method is labor-intensive and typically used for luxury materials such as silk velvet.

Modern production uses advanced equipment including:

| Type | Characteristics | Uses |

|---|---|---|

| Woven Velvet | Structured, luxurious feel, heavier weight, rich sheen | Jackets, evening gowns, blazers, upholstery |

| Knitted Velvet | Stretchy, soft, flexible, lightweight | Dresses, bodysuits, dancewear |

Designers and textile students must understand the many types of velvet fabric to make the right material decisions.

Velour is:

The following velvet properties help designers decide where and how the textile fits within a collection.

Classic, formal, anyone elegant appearance

Velvet is used across multiple industries. These uses of velvet cover apparel, accessories, décor, and more.

Skilled manufacturing partners, such as SEAM Apparel, often guide brands on how to manage and construct delicate materials like velvet during production.

Choosing velvet requires careful evaluation of performance, cost, and aesthetic goals.

Knit velvet may include spandex for performance or fitted garments.

USA-based brands often review these factors with their manufacturing partners before selecting production-ready velvet material.

Proper care helps preserve velvet’s softness and sheen.

Sustainability is a growing priority among apparel brands.

Modern sustainable velvet alternatives include:

Many manufacturers, including SEAM Apparel, help brands explore responsible sourcing options for velvets used in fashion and soft goods.

Velvet is a luxurious and historically rich textile that continues to evolve with modern manufacturing. Its plush surface, deep color saturation, and smooth sheen make it a timeless favorite in apparel, accessories, and home décor.

Understanding what velvet fabric is, its construction, and the many available types allow brands to choose the right version for each product. Whether designers prefer silk velvet for premium gowns, polyester velvet for durability, or cotton velveteen for structure, velvet offers endless creative possibilities.

With the right guidance in sourcing and production, velvet can add elegance and value to any collection. SEAM Apparel sports brands are looking to incorporate specialty materials and develop high-quality velvet products.

For deeper material guidance or support with product development, designers can reach out to a manufacturing partner knowledgeable in premium textiles