The process of developing a fashion design requires a garment tech pack, but not everyone creates one that is flawless.

This is partially a result of novice designers becoming alarmed when they encounter the word “technical.” Although clothing tech packs do contain some technical information, such as accurate garment measurements and language-specific vocabulary, they are not at a scientifically advanced level of technical, and even the language is simple to understand after it has been clarified.

If you want to start a clothing line or hire a factory to make your clothes, tech packs are essential. It contains all the necessary details to make the garment, much like a map or blueprint. For beginner designers as well as experienced designers, I’ll walk through the process of how to create tech packs for fashion garments in this blog.

Tech Pack

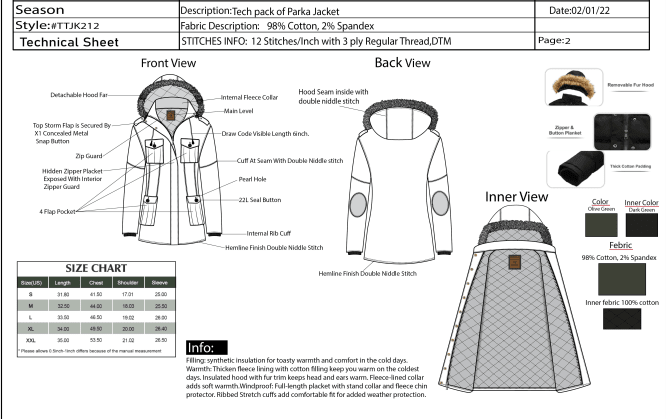

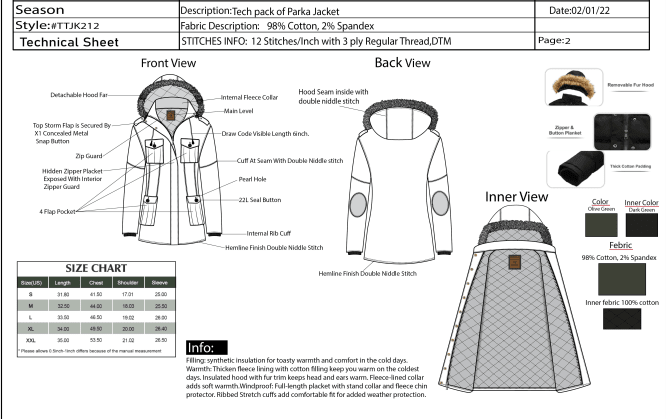

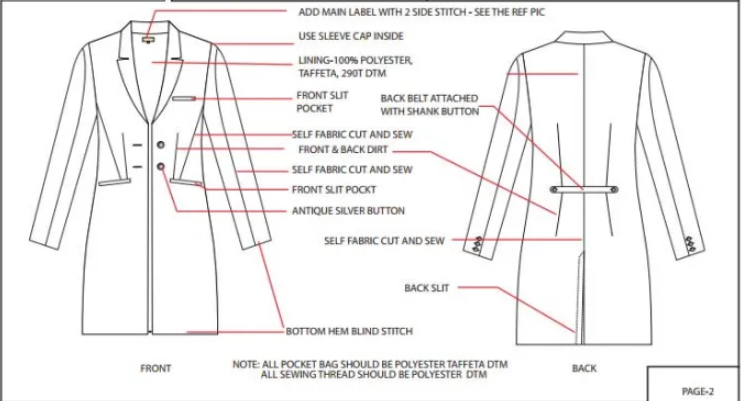

What is a tech pack in fashion? A tech pack, sometimes referred to as specification sheets, is a collection of documentation made by designers to communicate their idea to a manufacturer so that they may translate it into a finished garment. It functions as a blueprint for the finished item and contains details such as in-depth flat sketches of the design, materials to be utilized, such as trimmings and labels, measurement requirements, size gradings, colours, etc.

What Makes A Tech Pack Vital?

Tech Packs are essential for developing any fashion product, and these are just a few of the reasons why:

- You’ll save time and money: You can obtain flawless examples that correspond to your original concept with the aid of a thorough and simple-to-read Tech Pack.

- It facilitates precise price quotes: The more information you include in your tech pack, the simpler it will be for your factory to estimate how long it will take and how much it will cost to manufacture your goods.

- Tech Packs enhance the quality of the fit: A custom column called Fit Sheet can be added when a fit sample is obtained from the manufacturer, allowing you to enter the exact measurements. The initial measurements in the table can be compared to these actual measurements to see if the specific dimensions fall within the acceptable range. This greatly enhances the fit quality and offers you room to make the necessary adjustments.

- For quality assurance, it serves as a reference: You must verify the samples’ measurements, materials, and construction details for each round. If any of those stray from your criteria, you can inform the manufacturer so they can make the appropriate adjustments.

- You can work in teams more effectively: Designers, product developers, buyers, and quality control planners may all collaborate in a Tech Pack to produce better goods more quickly rather than just as a simple document.

What 4 Things Are Included In A Tech Pack?

A tech pack is often a document made by product developers, technical designers, and designers. Design sketches, dimensions and specifications, colour schemes, a material list with photographs, packing guidelines, maintenance recommendations, construction specifics, and much more are all included.

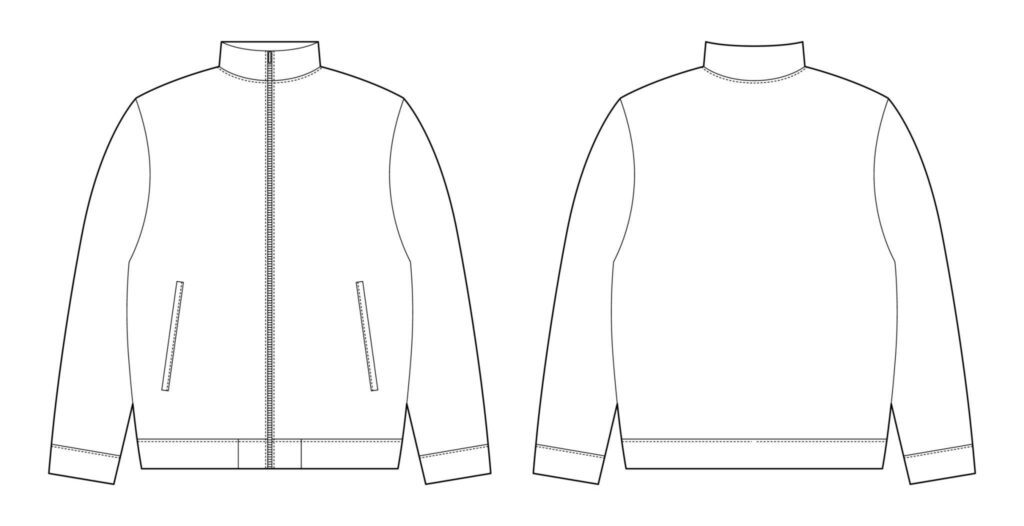

Flat Style Sketches

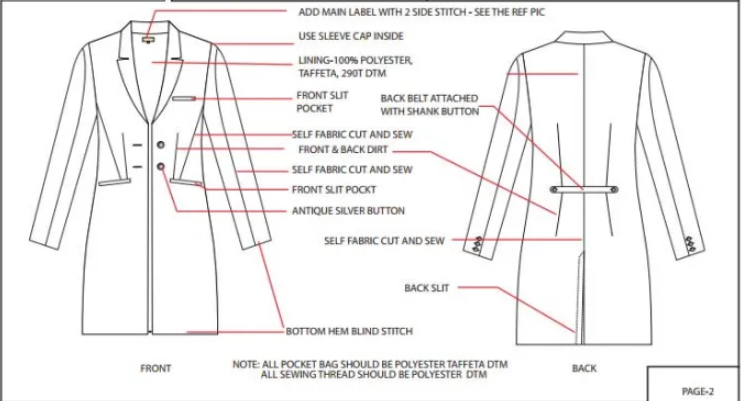

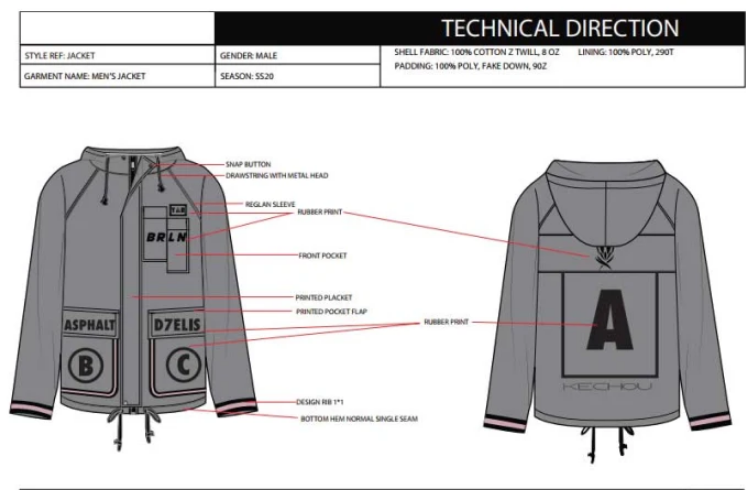

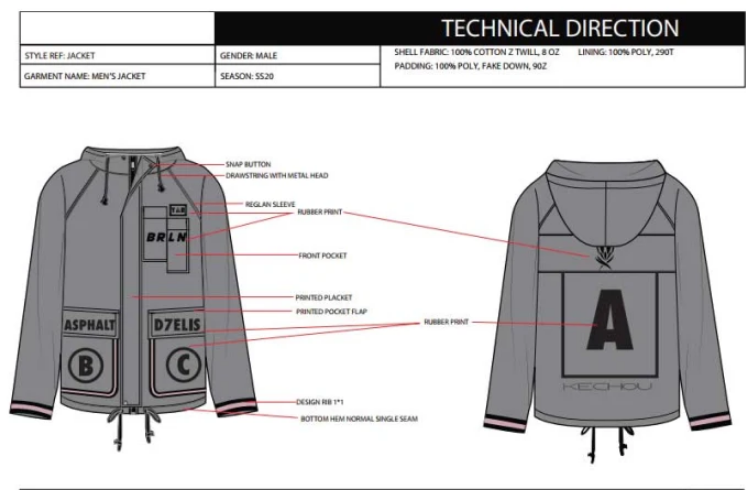

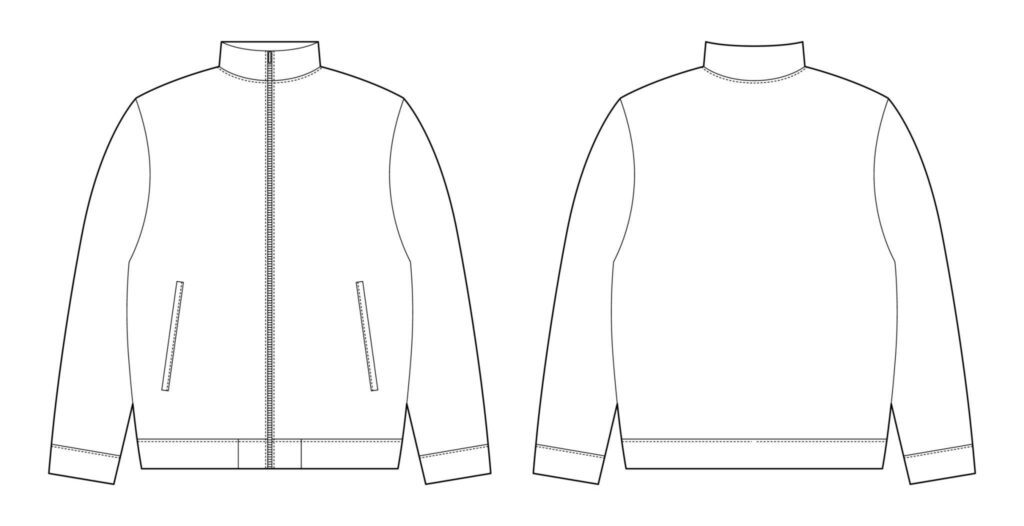

Technical sketches, often known as fashion flats, depict each design element from various perspectives (front, back, side, and yes, even inside). They aid your factory’s pattern maker in imagining how to make the prototype resemble your intended look as closely as feasible. They are usually produced using Adobe Illustrator and are hence black and white.

Before beginning your Tech Pack, it is crucial to confirm that your clothing or accessory drawing is complete. For your tech pack, use the following advice to generate polished flat sketches:

Include Several Views Of Your Clothing

It is simpler how to find a clothing manufacturer to understand the garment should be put together when you include a variety of perspectives, such as side views, interior labels, and other details. Any aspects regarding the clothing that aren’t clear from these sketches should be noted down. These frequently have schematics with arrows labelled to indicate the location of the artwork, fastenings, collars, plackets, and cuffs.

Give As Much Information As You Can

Pay great attention to details and be meticulous. It will be more challenging to communicate your design to the factory if you leave off some of your sketches. Every seam, dart, stitch, and button must be present for this to work. On a piece of clothing, a solid line usually denotes a seam, while a dashed line denotes stitching. Don’t mention a technical aspect in your tech pack that isn’t shown on your sketch!

Simple Is Best

Don’t overcomplicate anything; just add details to your sketches. To illustrate your idea clearly, stay away from shading and utilize simple black-and-white sketches.

MOQ

All manufacturers, as well as the suppliers who provide them with goods, have minimum order quantities, or MOQs.

Manufacturers must be aware of your MOQs and, in particular, your desired pricing to choose whether or not to accept your order. Depending on the size of the factory, a manufacturer will often require a minimum order of 30 garments.

It just isn’t worth the clothing manufacturers of custom designs getting involved if your order is below their MOQ because the time, money, and effort expended isn’t viable for their business. Although it is tough, it is business.

Manufacturers also need to know your order’s size distribution, therefore MOQs are important to them. This is because no manufacturer likes to keep a lot of fabric and material in stock, and manufacturers need to know how much to order. Why? Because it is expensive, takes up a lot of space, and requires your manufacturer to contact their supplier, who will also inquire about their MOQ.

Aside from materials and fabrics, if dyeing is required, your maker will also need to purchase and then mix a specific quantity of dyes to create a tech pack with your chosen hue. This has to be correct because only a particular amount of dye can make a certain number of garments.

Manufacturers won’t be able to find the best suppliers to produce your garments and are more likely to pass up working with you if you don’t highlight your MOQs in your clothing tech pack. To increase your chances, be sure to include your MOQs as well as your sizes (30cmx50cm, etc.) so that producers may start doing their calculations.

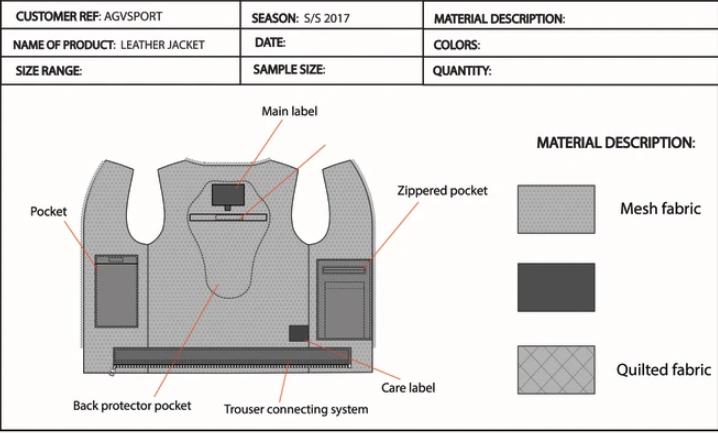

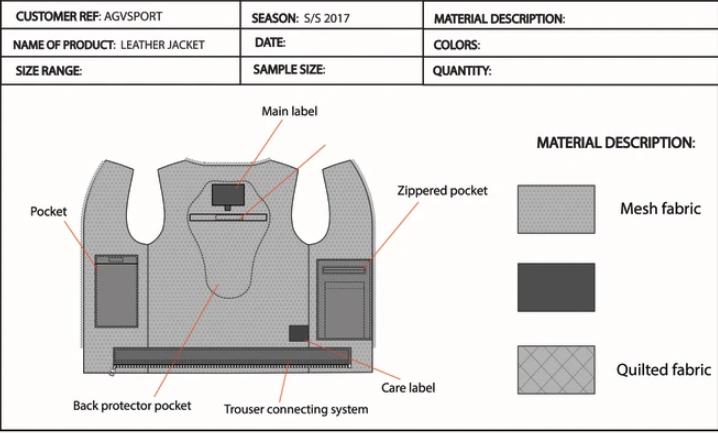

Bill of Materials (BOM)

All the materials are listed in this section, along with their placement, descriptions, quantities, and suppliers. The trimmings, threads, buttons, closures, labels, packaging, and other components that you add to your product are also considered materials.

Make sure to mention any extra buttons that will be sewn onto the finished clothes, as well as any components that go inside the item, on the back, or in between layers.

The BOM should include details on the material’s structure, weight (in grams per square meter), sourcing, and fibre content (the proportion of each fibre in the fabric). Include images of the fabrics, trimmings, and fastenings used how to create a tech pack for each part of the outfit.

The importance of a BOM table with clear parameters can be summed up in three ways:

- Figuring out the garment’s price and cost.

- To make sure that no components are missed by your manufacturer.

- To maintain uniformity and quality across all batches during manufacture.

Garment Measurement Specs

The next stage in constructing your Tech Pack is to include dimensions, presuming you have already established the design, set up the sketches, and created a materials page. The measurements of various parts of a certain garment are elaborately described in the measures specification sheet (also known as the measurement specifications).

Your method for measuring the distances on the garment should be noted on the garment specification page. The length and circumference of the sleeves, the collar circumference, and other details are all measured, for instance, on a button-down shirt tech pack.

The measuring points must also be represented visually. To show which measurement goes where on your technical drawing, provide arrows.

Aside from the sample size, which is the centre size of your range, don’t forget to include measurements for all the other sizes that your garment is offered in. A grading rule describes the measurements that separate each size. For instance, a T-shirt’s waist can range from a small to medium size by 4 inches.

Check out this reference book if you want to learn how to grade your work, but keep in mind that it’s a difficult procedure that’s best left to a qualified expert. This demo will show you how a skilled pattern cutter grades using software if you’re unfamiliar with the subject.

Regardless of complexity, all tech packs should have the following sections: garment spec sheets, grade rules, and measurement diagrams.

Other steps to follow:

- Grading/Details sheet

- Colourways

- Artwork

- Care Information

- Label

- Folding/Packaging

How Much Does Creating A Tech Pack Set You Back?

The cost of a tech pack will vary depending on the design’s complexity, however, in the USA, prices will range from $100 to $450 per design.

The cost is a typical deterrent we hear from potential customers. After all, spending that much money without getting a tangible product or sample is unreasonable.

Having stated that, a tech pack’s worth lies in its capacity to explain to a factory the particulars of a garment. As a result, you’ll find that the cost of a tech pack is frequently less expensive than the additional costs associated with sampling without one.

Depending on their complexity, tech packs can run anywhere from $50 to $400, to put things into perspective. For a client without a tech pack, there were typically 4.5 rounds of sampling, while there were typically 1.8 rounds for those who had tech packs. This indicates that among the sampling, those that generated tech packs saved an average of $375 to $935 per design.

However, some designers of gadget packs do make their prices apparent. The majority of them base their costs on what the tech pack is intended to do. Therefore, the price of the tech pack will be inexpensive if you only require it to be a basic one that a local tailor may use to make a few clothes.

Your tech packer will charge extra, though, if the document is for a major factory that produces fashion items in bulk and needs to include all the relevant information, such as care label specifications, grading, testing requirements, stitching construction, and packing instructions. As a result, the cost of fashion tech packs is negotiable with your designer.

How Long Does It Take To Create A Tech Pack?

It’s difficult to estimate how much time you’ll spend developing a tech pack. It will take longer to assemble a garment the more complicated it is. Even seasoned designers can spend 5–10 hours on more ambitious clothes while some straightforward pieces may simply take an hour or two.

The fit and manufacture process can take up to 4 months. It might modify even before the first fit sample is created. A tech pack’s production time is influenced by a number of variables:

You will cut down on production time if your files are organized effectively. It will be much simpler for the tech pack designer to list your original sketches if they are all saved in one location and have the necessary labels.

- Communication back and forth can take more time if you’re working with several manufacturers who aren’t accustomed to one another’s procedures and documentation design.

- It can be necessary to go back and redo some things if the design process needs some improvement in some areas (for example, due to sloppy sketching).

- If you created your tech pack using the most recent technology. If you’re utilizing outdated spreadsheet templates, you’ll inevitably be slowed down by an interface that’s not designed for visual data.

FAQs

What Are The Purposes Of Tech Packs?

Tech packs are used to instruct a clothing maker on how to make a product. It serves as a guide that is followed during the stages of mass manufacturing and sampling.

Can You Find A Pattern In A Tech Pack?

This will frequently depend on the services that the designer you select offers, but usually not. A tech pack’s size chart is frequently used as the basis for creating patterns, however, this is a separate service.

How Do A Tech Pack And Spec Sheet Differ From One Another?

Typically, a tech pack will contain a specification (spec) sheet as one of its pages. The aforementioned expressions frequently signify the same thing yet are used interchangeably. It’s best to address any questions with your clothing designer if you’re unsure.

Final Words

Tech packs might appear complicated, but they’re not. The procedure becomes simpler once you’ve broken out each step for how to make tech packs and made sure your clothing has specs, examples, and notes to help your producers. The more tech packs you produce, the more at ease you’ll become with them, and eventually you’ll understand how much information to provide.

Reduce the number of samples you need for creating a tech pack that is simple to use and traverse. This will also speed up the time it takes to launch your products.